02, 2020

by Oree Laser

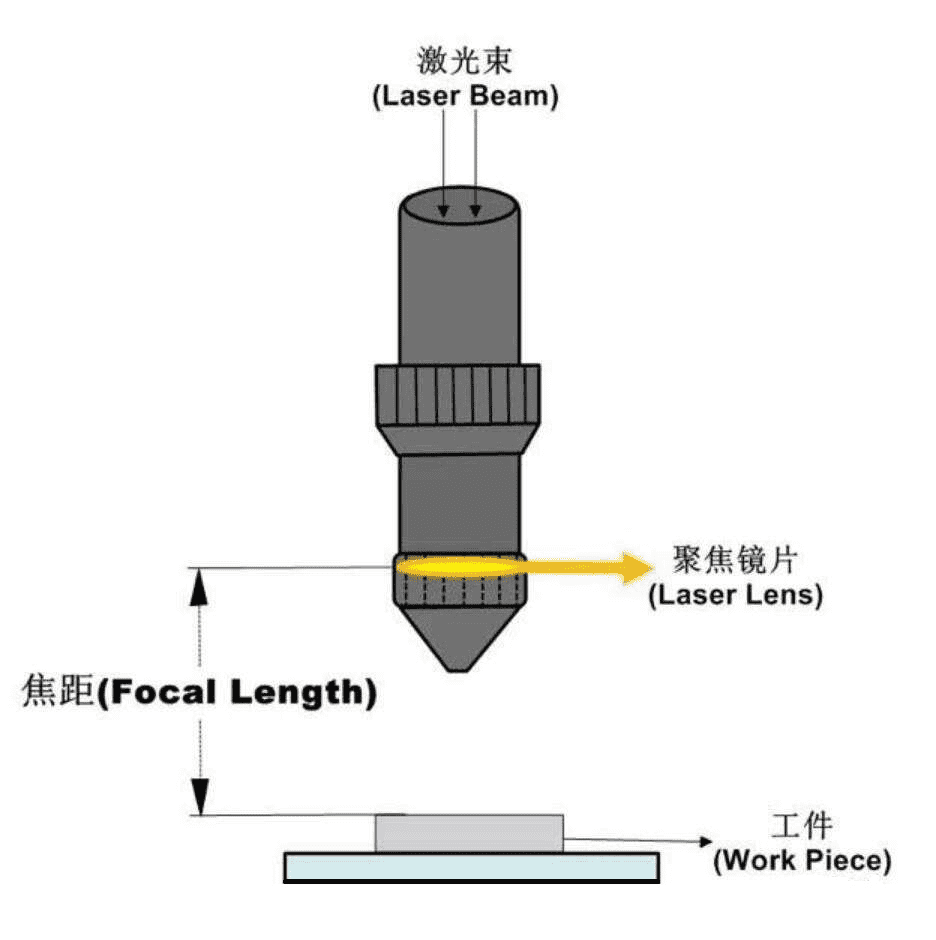

One of the advantages of laser cutting is that the energy density of the beam is high, so the diameter of the focal spot will as small as possible to produce a tiny slit. Because the smaller the focal depth of the focusing lens, the smaller the diameter of the focal spot. For high-quality, high-precision cutting, the effective focal depth is also related to the lens diameter and the material being cut, so it is very important to control the focus and the position of the surface of the cut material.

So what is focus control? When cutting different thickness plates, to show the perfect cutting effect, the focus of the laser beam will be set in different places. This is called focusing.

In the early days of laser cutting applications, manual focusing was relied on. However, with the development of laser technology, manual focusing will eventually be eliminated, and automatic focusing functions will be explored. For example, high-performance high-speedlaser cutting machines have automatic focusing functions. So, some people will say that the light path is integrated into the cutting head. Is it not easy to change the laser height? When the cutting head is raised, the focus position is high, and when the cutting head is lowered, the focus position is low. However, it turns out that it is not as simple as everyone thinks.

The bottom of the cutting head is a nozzle. During the cutting process, the distance between the nozzle and the workpiece (nozzle height) is about 0.5 to 1.5 mm. It may be regarded as a fixed value, that is, the nozzle height is unchanged. Therefore, the focus cannot be adjusted by lifting the laser head.

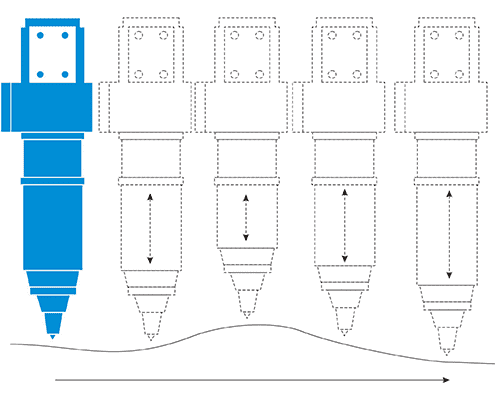

The focal length of the focusing lens is unchangeable, so it is not realistic to adjust the focus by changing the focal length. If the position of the focusing lens is changed, the focus position is changed accordingly:The focus lens goes down, the focus goes down, and the focus lens goes up, the focus goes up. This is indeed a way to focus. A motor is used to drive the focusing lens for up and down movements to achieve automatic focusing.

Another method of automatic focusing is: Before the light beam enters the focusing mirror, a variable curvature mirror (or tunable mirror) is set. By changing the curvature of the mirror, the divergence angle of the reflected beam is changed, and the focus position is changed.

With automatic focus function, the machine tool can automatically adjust the focus to the appropriate position through CNC when processing workpieces of different materials and thicknesses. This can significantly improve the processing efficiency of the laser cutting machine, and the punching time of thick plates will be greatly reduced. Therefore, for high-speed laser cutter tools, the automatic focusing function is important and indispensable.

All laser cutting machines launched by Oree have automatic focusing laser heads. The same laser head can quickly change focusing lenses with different focal lengths, adapt to various power processing, and meet the cutting of different thickness plates. By using the auto-focus function, users can finish cutting or engraving quickly and accurately, which makes the cutting or engraving work more time-saving and improves the user's work efficiency.

Professional Laser Cutting Machine Manufacturer - OreeLaser